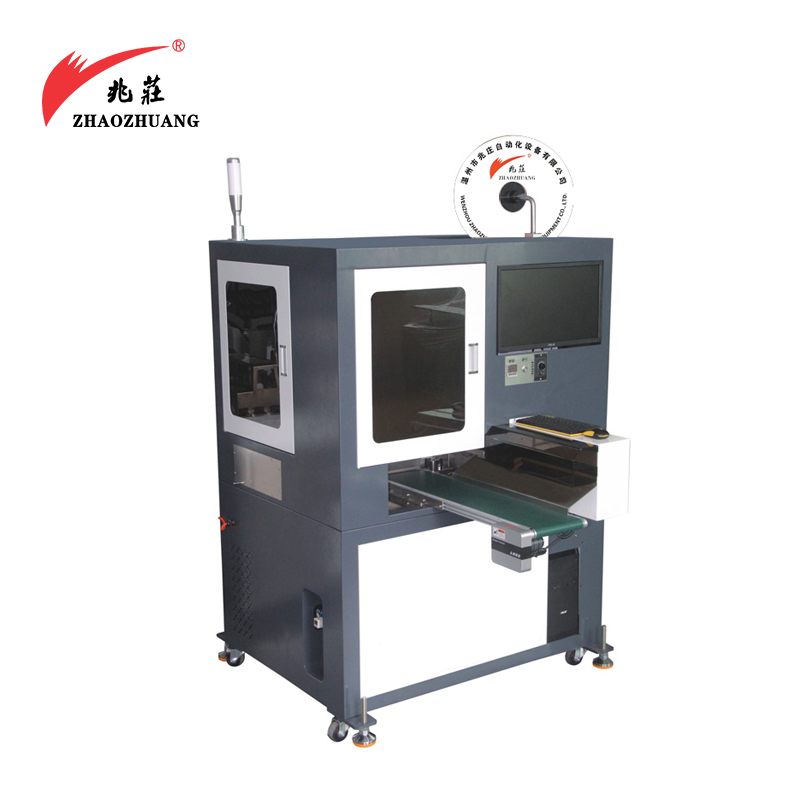

Automatic Single Head Plastic Shell Terminal Machine

Product Categories: Automatic Crimp Machine

Model: XC-8140

Brand: ZHAOZHUANG

Online Inquiry1. Realize the automatic wire feeding, cutting, stripping, twisting, terminal, inserting the shell, and the integration of quality monitoring

2. A variety of plastic shells only need to replace a few modular fixtures, simple and convenient

3. Suitable for electronic wire, flat wire, parallel wire, halogen-free wire, silicone wire, Teflon wire, braided wire and other wire processing, suitable for 1.0 terminal, 1.25 terminal, 1.5 terminal, PH, XH, VH series terminals, etc.

4. Servo control, pneumatic components, guide rails, etc. adopt world-renowned brands to ensure the overall performance of the equipment is stable

5. Optional terminal machine pressure management device, CCD visual image system, worry-free operation, quality assurance

6. Using touch screen man-machine interface, convenient parameter adjustment, simple and flexible operation

7. Possess a strong boredom ability, which can intelligently upgrade and expand equipment functions

Display

Touch panel

Function

cut, one end stripping crimping housing, one end stripping, half stripping, twisting, tinning

Support

CCD detection function

Detection function

Whether there is a wire, whether the wire is knotted, whether there is a terminal, whether there is a rubber shell, the air

pressure alarm, the motor is abnormal, etc.

Working efficiency

550-650 times/hour (if two connector, then 1200pcs/h, if 4 housing together, then is 2400pcs/h)

Cutting tolerance

0.5mm±L*0.2%

Cutting Length

30~1500MM support customized

Stripping length

1-9mm

Power

AC 220V/50/60HZ, 1300W

Air supply

0.5~0.7MPA

Machine size

3800*1800*2200mm

Machine Weight

550 Kg

+86-13656777668

+86-13656777668