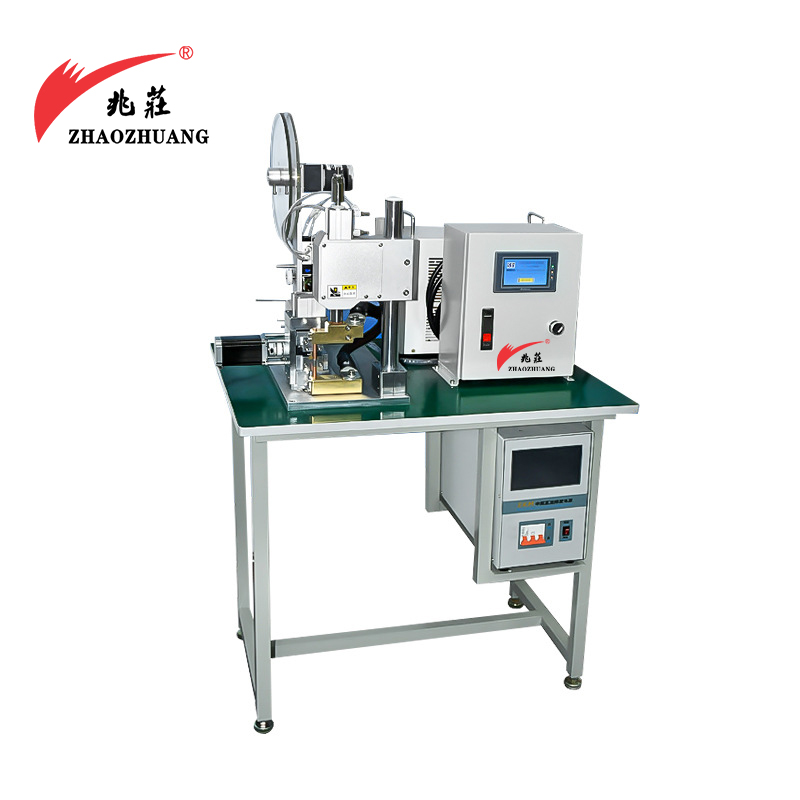

Inverter DC Spot Welding Machine

Product Categories: Ultrasonic Welder

Model: XC-6060

Brand: ZHAOZHUANG

Online Inquiry1. The load voltage is sensed, and the constant voltage is controlled by feedback to achieve high-quality welding.

2. The power-on method of PRE HEAT and MAIN HEAT is to preheat before welding to ensure stable welding quality.

3. Maintain the continuity of energy density, shorten the welding time, and reduce the deformation and discoloration of the base metal. (welding time

Control in microsecond unit, continuous output mode)

4. Easy to change from low current to high current, suitable for precision welding.

5. The upper and lower limits of the current can be set to simply judge whether the welding quality is good or not, suitable for automatic welding

chemical instrument.

6. The welding current rises with the energization time to ensure the welding result.

7. Static current control of load (LOAD) current inspection and change mode is conducive to high-quality welding control

8. 4KHz high-frequency modulation inverter control is conducive to high-speed response and high-quality welding control.

9. The use of 2-stage power-on function is beneficial to overcome the coating problem of the welding workpiece and adapt to various process requirements.

10. The function of slow rise and slow fall is beneficial to suppress the spatter phenomenon in welding, and the switching of 8 kinds of welding specifications is beneficial to welding

During connection, the welding parameters can be quickly changed according to different welding requirements.

11. Various welding information and welding parameters are displayed on the 20*4-line liquid crystal display, which is convenient for checking the welding results

confirm.

12. It has the function of comparing the welding result with the parameters of the equipment, and judging whether it exceeds the set value, and then judging the output

Normal (GO) or abnormal (GN) displays and signals.

13. It has the function of continuous setting of welding current and switching function for 8 sets of welding parameters stored in advance, and has the function of

The welding detection function can control the welding quality and ensure the welding quality. This device

It is an inverter welding equipment developed for industries that require high-quality welding.

14. It has the function of slow rise and fall of current, and has the function of 2-stage power-on output, which can be adapted to a variety of welding

Welding of materials and various welding process requirements.

| Model XC | XC-6060 |

| Input current | 3 Phase 380V / AC 220V±10% (50/60 Hz) |

| Output current | 5000 A |

| Rated capacity | 8.5 KVA |

| Control mode | Constant-current control |

| Inverting frequency | 4 kVA |

| Memory capacity | 8 programs |

| Application | Rechargeable battery electrode, sensor |

| Operating temperature | 0 - 50 degree |

| Operating humidity | 5-55 % |

| Weld arm | Retract and swing |

| Distance between electrode and machine body | 80 - 95 mm |

| Pneumatic cylinder diameter | 25 mm |

| Pneumatic cylinder stroke | 20 mm |

| Electrode diameter | 3.0 mm |

| Min. electrode distance | 0.1 mm |

+86-13656777668

+86-13656777668