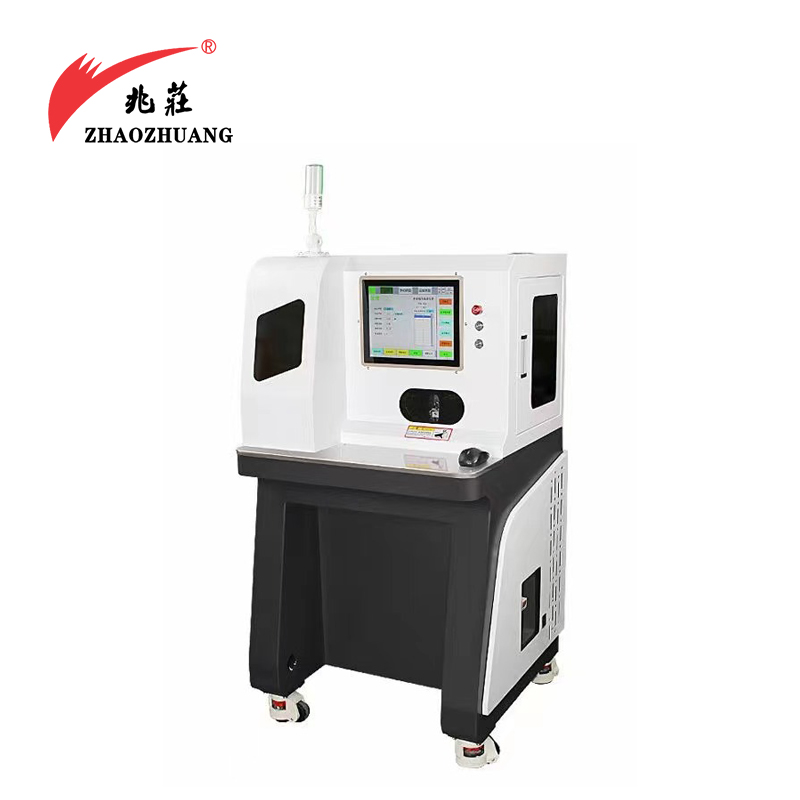

Tube Type Insulation Number Tube Terminal Machine

Product Categories: Terminal Crimp Machine

Model: XC-5010C

Brand: ZHAOZHUANG

Online Inquiry1.The program for various materials can be stored and called at any time, and different printing fonts can be numbered for circular production, which is precise and convenient. Compared to manual tube printing, it is less prone to errors. Optional Mesh interface

2.Integrated wire clamping, wire feeding, peeling, and pipe threading

3.There are pressure alarms, fault alarms, and other alarm devices available

4.Assembling a Shuofang typing and threading number tube machine, integrating threading and printing can save you 1-2 operators

control mode : Human machine interface, electronic touch, pneumatic control

Operation mode:Automatic trigger operation and manual operation

Wire number specifications:Suitable for BVR lines of 0.5, 075, 1.0, 1.5, 2.5, and 4.0 square meters

Stripping Length :Stripping length range 8-16mm

Terminal specifications:Terminal insulator length within 7.5mm, conductor length within 12mm

Crimping shape:Quadrilateral crimping (square like)

Replace the product:Manually replace relevant fixtures and adjust vibration discs, electric memory peeling length and depth. Replacing a set of terminal fixtures takes about 3 minutes

Testing items:Terminal detection and right side safety door opening detection

Power supply:External input power supply AC220V/50H (single-phase) 10A: Internal power supply DC24V

Gas source:0.5-0.8Mpa (Please use a stable, clean, and dry air source, and maintain a pressure of no less than 0.5Mpa when connected to the air source)

External dimensions:L730 * W760 * H1400mm (excluding protrusions)

Weight:100KG

Number tube length:10-32mm

Sheath peeling length:275mm (specific sample confirmation)

speed:About 650PCS/H

+86-13656777668

+86-13656777668