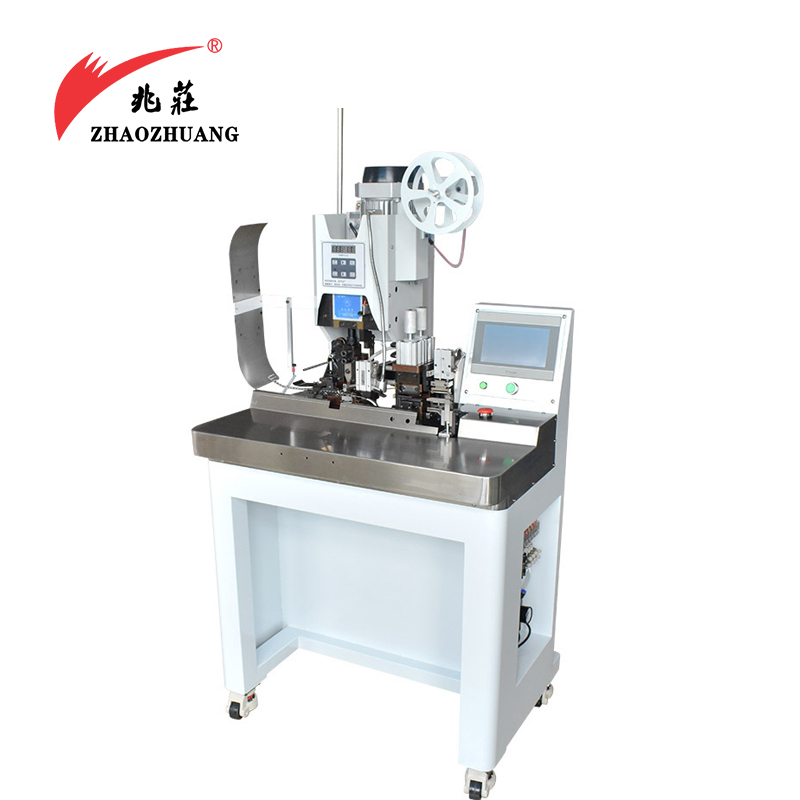

Multi-core Continuous Cable Stripping Crimping Machine

Product Categories: Terminal Crimp Machine

Model: XC-50F

Brand: ZHAOZHUANG

Online InquiryThe multi-core sheathed cable stripping and ferrules crimping machine is especially designed for processing the core wires of multi-conductor sheathed cable. The outside jacket should be pre-stripped before using this machine.the advanced frequency conversion technology, intelligent control, when weld, the machine start to work, compared with the traditional terminal machine, the noise is smaller , power consumption reduced by 50%,installation mold is more quick and convenient,avoid the common faults of traditional terminal,such as clutch,electromagnet and so on. * The multi-core sheathed cable stripping and ferrules crimping machine can complete wire feeding, inner core stripping, terminal crimping accurately and continuously.

* This machine is especially designed for processing the core wires of multi-conductor sheathed cable. The outside jacket should be pre-stripped before using this machine, and the operator only need tro place the cable in the working position, then the machine will strip wire and crimp terminal automatically. It greatly imporoves the multi-core sheathed cable processing effeciency.

* The control system adopts PLC and color touch scree, the moving parts are driven by servo motors, simple operation and high processing accuracy.

| Model | XC-50F |

| Cable type | Multiple conductor cable, flat cable etc. |

| Cable outer diameter | 1.3 - 32 mm (0.052 - 1.259 inches) (larger cable can be customized) |

| Conductor size | 30 - 16 AWG |

| Conductor number | 2 - 20 (depending on the cable type) |

| Stripping length | Depending on conductor size |

| Crimping force | 1.5 T |

| Applicator | OTP |

| Productivity | 3600 pcs./h (depending on the wire type) |

| Power supply | 110, 220 V (50 - 60 Hz) |

| Power | 750 W |

| Dimension (L * W * H) | 800 * 600 * 1250 mm (31.50 * 23.62 * 49.21 inches) |

| Net weight | 145 kg (319.67 lb) |

+86-13656777668

+86-13656777668